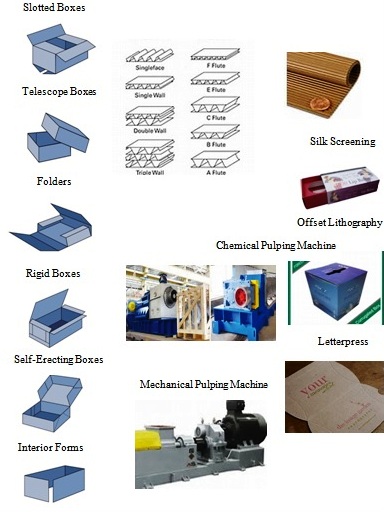

Corrugated means that there is paper with fluting (arched layer) between liners (flat sheets); the arched layer provides corrugated with a good weight to strength proportions. Corrugated fiberboard is usually used for making boxes and there are many different forms this type of package can take; the flutes can be different sizes and there can be a different number of flutes for the packages. Flutes, the board between the liners, is used to make the box strong. To make the shape the flutes have, rolls of paper are inserted into a corrugated roller machine. Single letter flutes are used to describe boxes that are single wall, and similarly, double letters represent double walls; the double letters also represent the top and bottom layers of board. Corrugate products are versatile, sturdy, and economical; they are even modified to fit the producer’s desire. Whether that desire is packaging or for another reason, like furniture, displays, or even containers.

Corrugated boxes have so many uses because they are constantly being used and improved; whether it is about improving the challenges faced by consumers such as: humidity that weaken down the boxes, reusability, and improving the strength of the boxes. To protect against humidity, corrugated packages are being made to withstand any type of pressure, whether it is inside, or being transported anywhere. For reusability, the boxes are made with large amounts of fiber, which is salvaged from other containers. Because this type of packaging is constantly being reused, better than any other frequency of materials recycled, 92 percent of all containerboard produced was recovered in the United States. Not only do producers want to make sure the packages fit the requirements, but they also want them to be visually appealing. There is an extensive variety of printing options to make designs pop on the packages. A few of those options are: silk screening, offset lithography, and letterpress.

Corrugate has been around for hundreds of years, so it is no surprise that it can be molded so many ways. It started in the 1600s with papermills and then expanded in the 1800s. Unlined corrugated was the first on the scene and it was used for chimneys and as a packaging for glass. Decades later, one side of corrugated packages were made with a liner to keep the flutes intact; and after that, the single wall for corrugated items was created when there was a second liner laced in the boxes. When the 1900s came, different types of machines were being made that could improve the look and design of corrugated packages.

There are around 1,300 manufacturing plants in the U.S. and Canada combined, bringing in 26 billion dollars between the two. Of the 1,300 plants, 70,000 of those workers are employed in the United States. Because of its efficiencies in the world, the amount of corrugate needed to make industrial production function, has been decreasing since the 2000s.

Making the Boxes

When creating corrugated boxes, there are two different liners; the outer liner uses Kraft paper, and the inner liner uses test paper. Kraft paper is stronger because the tree it is made from has long fibers; the trees that contain these fibers are called softwood trees. Short fiber trees are made from hardwood or recycled paper, which explains its lower quality.

In the beginning of the process, the trees are debarked and chipped after they’ve been sent in through a machine when they’ve been cut into logs. There are two different processes a chip can go through when it comes out of the machine, “cooking” or “grinding”. Chemical pulping, “cooking”, is when sulphite or sulphate is used to condense the chips into wood chip pulp. Sulphate is usually the more preferred of the two, it uses alkaline solutions to digest the wood, while at the same time adding sodium sulphate to increase the strength of the pulp. Even though the sulphate process is preferred or the sulphite, they both are used in the Kraft process to create better quality paper. Mechanical pulping, “grinding”, condenses the wood into wood chips by using a revolving stone to push the logs against each other. Mechanical pulping is not that expensive and produces at a quick rate; but it doesn’t remove much of the lignin.

For the production, the corrugated paper is sent through rollers where it is hot steamed and glued to one side of the flute. Next, the cardboard is cut to have straight sides by a circular saw; and then it is sent into a corrugator machine to be cut and separated into stacks. The size of the board determines how many times the machine is going to cut it. The next step is to cut in the details of the board; this can be done with pointed rubber blades, or with a die-cutter. To form the actual shape of a box, the box is sent into a bending machine and then is either glued or stitched. The process ends with the boxes being sent through another folding machine to hold the flaps together tightly; and any extra material is reused for future projects.

Recycling

It is clear why old corrugated containers (OCC) are used over from previous projects; in 1992, OCC made up 18% of all civic solid waste entering the country’s landfills and 26% of the industrial waste stream. To keep this waste from polluting the country, measures were taken; not only to recycle, but to improve the environment from it. Certain companies that are devoted to sustaining forests, also have fiber sourcing programs that supply material that 96% of corrugated boxes are made with. And because a few companies started the wave for preserving our trees and nature, millions of trees are being planted every day and the U.S. forest area is increasing; it has been since the year 2000. Almost 50 years later, the U.S. has about 20 percent more trees now, than it did in 1970. In 2015, 92.9% of corrugate produced was recycled. Corrugate is the packaging material recycled the most, and it is thriving.

All these things can be done because of the fiber that is in the corrugate, which is about 47% percent typically. For the recycling process, old corrugated containers need to be clean and without impurities, if they’re clean they are collected and put into bundles for handling. Bales are then moved to paper mills where the OCC are put into a re-pulper to combine water and the fibers from the materials, into a mush. The mush is then cleaned out by a chain that is revolving in it. Whatever is left over in the mixture that didn’t come out from the initial cleaning, is sent through machines that can pull the impurities from the bottom of the vat. The mixture is then removed of its water and sent through rollers to ensure that the mush is free of water. To remove excess moisture, the mixture, now in the shape of a mat, is sent to dry in drying cylinders. Next, the mat is then rolled up on a reel to produce smaller rolls, turning it into paper that can be reused again. To create a corrugated board, the sheet of paper is fed through a single facer after its been steamed, giving it flutes. After it has been placed between the two sheets with a bonding agent, it then becomes a linerboard. Once the recycling process is complete, the product that was at first corrugate, is now a material that can be used for whatever needs a consumer has.

References

“Recycling Corrugated Cardboard.” Infohouse.p2ric.Org, infohouse.p2ric.org/ref/01/00012.htm.

Tim Brown. “How a Cardboard Box Is Made.” The Manufacturer, 18 Sept. 2014, www.themanufacturer.com/articles/how-a-cardboard-box-is-made/.

www.RadiaInteractive.com, Development by. “Fact Sheets.” CPA - Fact Sheets, www.corrugated.org/?l=fact_sheets.

www.RadiaInteractive.com, Development by. “What Is Corrugated?” What Is Corrugated? - Detailed Information on Common Board Styles and Flutes, www.fibrebox.org/Info/WhatIsCorrugated.aspx.