This paper discusses the importance of packaging relating to red meat, specifically beef, and how it pertains to not only distribution and shelf life, but also how it can influence retail sales to consumers. Consumers in industrialized and developed countries are presented with a variety of packaging options when visiting the local grocery store. Some meat is presented behind a glass counter where you can select what steak or ground beef you want and have a store worker package it for you. Other meat is prepackaged where you can pick up what you want quickly. Meat packaging serves many functions, some of which the customer may not see or appreciate. Therefore, in the following sections, we will discuss these functions to provide a more robust knowledge of the various types of packaging and why they are used.

No discussion would be complete without first looking at how we got to where we are today. First, let’s look at the development of meat packaging and preservation. There were very few preservation methods available to the earliest civilizations so they would eat what they killed daily. As civilizations continued to evolve and become more nomadic the need for transporting and preserving food grew. Some of the first methods of preservation can be dated to 3000 BC in the Mesopotamian regions3. The Egyptians and the Sumerians were some of the first to use salt to cure meat as well as various oils to preserve meat in jars for storage and transport. They would even dry meat in the sun to make jerky, which was also an effective preservation method. These types of preservation and packaging continued with some of the world’s greatest civilizations such as the Greeks and Romans. The Greeks continued to use salt to cure meat and even began to smoke meats for preservation3. The Romans also cured meat. This type of preservation was predominately used up through the end of the 19th century. Salted pork was a common wartime meal in both the Revolutionary and Civil Wars in the United States. The character “Uncle Sam,” which has become synonymous with the United States, got its origin during the war of 1812 from a meatpacker named Samuel Wilson. He would package salted pork in barrels and stamp them with the initials “U.S.” and then send them to the United States Army. The soldiers started to refer to the “U.S.” stamps as being from Uncle Sam2.

In the late 19th century and early 20th century, communities in the United States began to spread out further west and railroads began to be built. The railroads allowed for the connection of well-established communities in the east with smaller more remote areas in the west, which helped with transporting people and supplies. Not only that, but people’s taste in food began to change causing people to want fresher meat that was not altered in flavor by salt or smoke. Luckily, with the new railway system along with the development of refrigerated rail cars, small packaging plants began to pop up near populated areas. These packaging plants were able to serve surrounding rural communities with fresher beef. Whole sides of beef were shipped to local butchers and smaller cuts were made and sold to the customer.

During the early 1900s, meat packaging plants were growing in bigger cities such as Chicago and New York. Workplace safety and hygiene in these packaging plants became critical as there was little to no regulation. It wasn’t until Upton Sinclair wrote the book The Jungle that people became more aware of what was happening in packaging plants. The book was written to show some of the inhumane and unhygienic practices that were commonplace in the slaughterhouse and packaging plants. The book created so much outrage among the public that the United States Congress had to act and instituted the Federal Meat Inspection Act of 1906. This was the first major legislation passed to help regulate the meat packaging industry. The next advancement happens in the 1960s as boxed beef came on the scene. This is where sides of beef are cut down into primal and sub-primal and vacuum sealed. As packaging technology advanced and populations grew larger, beef packaging and production moved away from the in-store butchers towards large, centralized packaging facilities. Now that we know the history of meat packaging, we can discuss the advantages and disadvantages of certain types of packaging and why they are used.

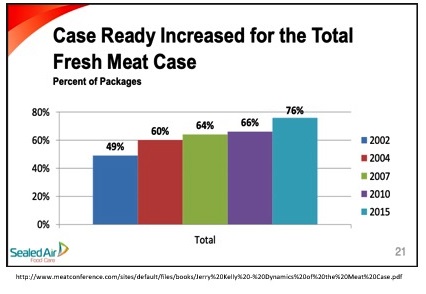

There are many types of materials and processes used in modern meat packaging facilities, some of which the customer see in the final package that he or she purchases from the store and some components of which they do not see. Many of the packaging options are referred to in the industry as “Case-Ready” which is defined by the North American Meat Institute (NAMI) as “any meat that is packaged in a meat processing plant and ready to be placed directly into display cases upon arrival at a retail store”4. Case-ready packaging has been increasing in popularity among producers and consumers over the past decade. The chart below shows the increase in presence that case-ready packaging has had in the fresh meat case from 2002 – 2015. There are many reasons why this type of packaging is continuing to gain momentum. The NAMI lists several reasons in their case-ready fact sheet which include:

• Less labor and therefore cost savings for grocery stores due to the lack of people needed to handle the beef.

• The ability to order certain cuts that are selling well while avoiding less popular cuts which don’t sell and end up as waste.

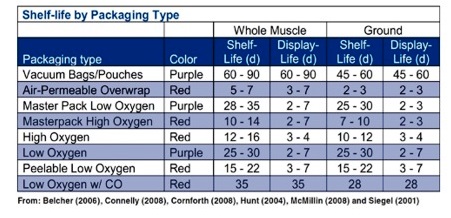

• Longer shelf life – up to 28 days from production facility.

• Better ability to control inventory4.

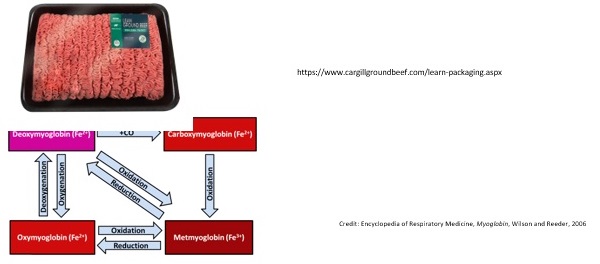

All these benefits ultimately result in a better experience for the customer in terms of value and consistency. The main attribute that customers look for when purchasing their beef is a nice fresh color. It is estimated that 15% of all retail beef is discounted due to color variation. It’s also interesting to note that the optimum color that customers look for can vary by where you are in the world. For instance, Europe is more accustomed to receiving vacuum packaged meat which is more purple in color than what is found in the United States. While both are perfectly fine to eat, customers in the United States prefer a bright pink color, which is associated with freshness4. Let’s take a closer look at the three different types of modified atmospheric packaging and see what materials are used and discuss the benefits and negatives of each.

Vacuum Packaging

Most people are familiar with the concept of vacuum packaging. Essentially, the meat is placed within a bag and all the air is removed and the bag is sealed. The principle behind vacuum packaging is to remove all the oxygen from the final package to prevent spoilage mainly contributed by the aerobic spoilage microorganism Pseudomonas spp. as well as oxidative rancidity. It should be noted that this does not inhibit the growth of pathogenic bacteria such as Escherichia Coliforms and refrigeration/freezing is still needed to inhibit the growth of these microorganisms9. From an operational standpoint, a quality vacuum sealer is needed, but more importantly, the right packaging film is required. In most cases, a coextruded laminate of two materials is used, where polyethylene is used as the inner layer of the film mainly due to it being economical. However, because of its barrier properties, a second film is needed to provide the barrier properties required for packaging. In the case of vacuum packaging for meat, the common films used to provide the needed barrier properties are Polyethylene Terephthalate (PET), Polyvinylidene Chloride (PVDC), and Polyamide. PET has very low gas and oxygen permeabilities, high strength, and good printing characteristics. One of the main drawbacks of the film is that it has a high melting point of 545oF, which is why it’s often paired with PE for sealing practicality. PVDC also has excellent barrier properties and is often used in pharmaceutical packaging because it has good grease, oil, and chemical resistance. PVDC is also commonly known by its trade name Saran. Polyamide’s barrier properties are very good as well and it is also a very strong film. One advantage of unoriented polyamide is its ability to be thermoformed and shaped easily6.

There are many advantages to vacuum packaging. For starters, there are relatively low operational costs, and it is easy to pack. Consumers can get long shelf life because the vacuum can pull out 75-85% of the air within the packaging Shelf life can be as high as 70-80 days with proper refrigeration (28-32oF)6. Interestingly, if vacuumed sealed beef is kept below 0oF, it can be kept indefinitely, but it is best eaten within 12 months of freezing. This feature also makes vacuumed packaged beef ideal for exporting beef overseas. The main disadvantage, however, is the color of the meat at the point of sale. As mentioned earlier, color is one of the most important factors for consumers regarding their perception of freshness. Meat color is determined by the oxidation of the pigment Myoglobin which consists of two parts, a globular protein (globin) and a non-protein portion known as a heme ring. It is the state of the iron within the heme ring that the color of the meat is determined. When the meat is deprived of oxygen and the iron is unoxidized such as in vacuum packaging, the pigment is purple and called deoxy myoglobin. Once oxygen is introduced to the meat, the pigment starts to oxidize, and the color “blooms” to a nice bright pink color called oxymyoglobin. If allowed to continue oxidation the pigments will turn a dull brown called metmyoglobin8. Customers within the United States are very used to the bright pink color and associate that color with freshness. While there is nothing wrong with purple or brown meat, customers want the freshest product.

High Oxygen Packaging

High oxygen packaging was developed because of color being attributed to freshness. The oxidation of meat initially causes a “bloom” in red color created by the oxymyoglobin complex. Simply put, high oxygen packaging is the method where gas made up of 80% oxygen and 20% nitrogen is pumped into the package with the meat before sealing. This method utilizes a deep, rigid polystyrene tray with a flexible oxygen barrier film on top5. This was one of the first case-ready MAP options utilized.

The main benefit of high oxygen MAP is that the shelf life is slightly increased by ensuring that the meat retains its bright red color in the retail cabinet. This type of packaging is becoming less popular because even though the “fresh” color is maintained, the high levels of oxygen also increase lipid oxidation, which can lead to the faster onset of rancid smells and flavors as well as the increased conversion of oxymyoglobin to metmyoglobin (brown color). Therefore, there is a tight window for retailers to sell the product.

Low Oxygen Packaging

Low oxygen MAP has been increasing its footprint in the meat case over the past several years. The concept of low oxygen packaging is very much akin to vacuum packaging. The objective is to remove the oxygen within the packaging to reduce oxidation and prolong shelf life. With low oxygen master packs, we can achieve similar results while maintaining a package that is appealing to the customer. This process involves meat being portioned out on traditional foam trays in an automated process. The meat is then wrapped with an outer film that is oxygen permeable. The trays of meat are then sent through a flow wrapper where a certain number of trays are packaged into a mother bag containing a mixture of three gases. The typical gas mix is 69.6% nitrogen, 30% carbon dioxide, and 0.4% carbon monoxide7. The carbon monoxide is added because it can oxidize the heme ring forming carboxymyoglobin, which assists in prolonging a bright red color. The tri-gas replaces atmospheric air in the package, which eliminates the reaction with oxygen. To boost oxygen removal, an oxygen scavenger sachet is added to the mother bag. Once packaged, the mother bags are stacked and stored in a cold room where the meat will turn purple due to the lack of oxygen. Once the mother bags are shipped to the retailers, store workers remove the packaged meat trays from the bag and allow them to rest overnight in a regular atmosphere. During this time the oxygen permeates the film and allows the meat to bloom back to the characteristic bright red color that customers desire.

The benefit to this type of packaging is the ability to achieve an extended shelf life while being able to present a product that customers desire. Also, this allows for centralized distribution and production, which enhances the quality and allows for stores to reduce inventory levels. The disadvantage to low oxygen master packaging is that the capital costs of the production line can be high for producers, which increases the cost to consumers. There is also some negativity surrounding the use of carbon monoxide in the packaging. Many European countries are still somewhat hesitant about this type of technology because of the use of carbon monoxide. However, carbon monoxide has been used in meat packaging for over 24 years and the United States FDA listed carbon monoxide as safe in food packaging under certain limits1.

Final Thoughts

Packaging for meat has come a long way in the past 100 years. Population density, packaging safety/hygiene, and cost have all contributed to the development of better methods. Vacuum packaging and low oxygen master bags are the most common methods in the United States. Countries with large geographic areas and spread-out populations will benefit from centralized packaging and shipping centers. Above all, the packaging must help meet the needs of the consumer.

References

North American Meat Institute Fact Sheet – Carbon Monoxide in Meat Packaging: Myths and Facts:

https://www.meatinstitute.org/index.php?ht=a/GetDocumentAction/i/60863

Was a 19th-Century Meat Seller the Inspiration for “Uncle Sam”? https://www.history.com/news/was-there-a-real-uncle-sam

History of Meat Curing Process. https://foodprocessinghistory.blogspot.com/2013/05/history-of-meat-curing-process.html

North American Meat Institute Fact Sheet – Case Ready Meats Modified Atmospheric Packaging. https://www.meatinstitute.org/index.php?

ht=a/GetDocumentAction/i/93528

The Case for Case-Ready Red Meat. https://www.ift.org/news-and-publications/food-technology-magazine/issues/2004/august/columns/packaging

Dr. Narendra Nayak. Meat Packaging. http://www.ndvsu.org/images/StudyMaterials/LPT/meat_packaging.pdf

Packaging Systems for Meat – Wholesale and Retail. https://meat.tamu.edu/ansc-307-honors/meat-packaging/

Aberle, Forrest, Gerrard and Mills. Principles of Meat Science 5th edition. Kendall Hunt, 2012.

Beef Shelf-Life Fact Sheet. https://www.beefresearch.org/resources/product-quality/fact-sheets/beef-shelf-life