Various colors of glass are very commonly used in the packaging of drinks, oils, and various other fluids. The making of colored glass as a type of packaging is very interesting because all glass is different, and no two colors are made using the exact same method. The color of glass bottles has different uses as well, with some colors providing UV protection, some being more resistant to chemicals, and some simply being more visually appealing than others. The most common types of glass used in commercial packaging are Soda Lime glass and Borosilicate glass which is stronger and more resistant. Commercially, colored glass has been hugely successful and is used by many companies for its visual appeal, the fact that glass is cheap to produce due to the abundance of materials used to make it, and the many things that can be stored in it.

Soda lime glass, which makes up about 90% of commercial glass, is usually composed of about 70% silica (silicon dioxide), 15% soda (sodium oxide), 9% lime (calcium oxide), and various other compounds depending on the use and desired color of the glass. When coloring soda lime glass there are four main colors which are produced including clear, amber/brown, green, and blue, depending on the purity of the glass and what other compounds are combined with the soda lime mixture. There are many combinations and variations of these four that can be achieved using different methods. However, these are the colors most seen commercially.

Borosilicate glass is usually more colorful than its soda lime counterpart. Borosilicate glass is comprised of about 80% silica but instead of a higher concentration of calcium oxide, it is about 13% boric oxide, 4% sodium oxide, 2% aluminum oxide, and again various other metals depending on what color is desired. Borosilicate glass is mixed with different metal elements to produce many different colors and is usually more commonly used in colored glass because it is more thermal resistant than soda lime glass and can better survive the many different methods used to create colored glass.

Iron oxide is the main component in determining the color of most soda lime glass. The iron’s concentration and ion ratio can produce all three of the main colors seen in soda lime glass. Chromium and copper are also used with soda lime glass, with chromium creating more shades of green, and copper making it possible for a few other special colors. Amber/ brown soda lime glass is what most beer bottles are made of and is a resultant of iron-sulfur-chromophore in the soda lime mixture. This amber color is UV resistant which protects the beer or any other product that is UV sensitive. Cobalt can also be mixed with soda lime glass to create a blue glass.

Borosilicate glass mixed with trace other elements and compounds can produce many more different colors that are still being discovered today. The main color causing ingredients in the mixtures for borosilicate glass are rare earth and other metals.

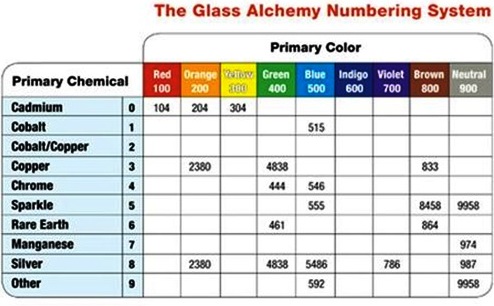

· The 1st number in each box correlates to the color, e.g. 100 = red 200 = orange

· The 2nd & 3rd number indicates the primary chemical additive

· The 4th number indicates the colors saturation level

· Sparkle obviously isn’t an element but in this case refers to dichroic material which can be mixed with any color glass to create a shiny chrome-like visual

https://cdn.shopify.com/s/files/1/0965/6730/articles/numberingsystem_large.jpg?v=1523296166

These are only a few of the possible colors that can be created from metals and glass. Along with the many different possible colors of borosilicate glass there are different ways of processing these colors. The processes used for glass coloring is the simple mixing of the metals to get a uniform color, staining, overlaying, lustering, casing, and dichroic glass making. These processes create a different effect using colored glass. The color is still created from the mixing of the metals with the original silica mixture, but many different effects can be created with this colorful glass.

Not all of these processes fully color the glass but they do all affect the overall visual color of the glass. Stained glass is something most people have seen and is created by brushing the metal oxide onto the finished piece and is then reheated so that the color will set. Overlaying is used in several ways by blowing a ball at the end of glass blowing pipe and setting the ball into a pot of molten colored glass before the ball has set in shape. Lustering is a very pretty process that creates a rainbow sheen to a piece of glass. To create a luster on a piece of glass metal oxides are placed inside the heating chamber to vaporize and lightly color the piece of molten glass. In casing multiple layers of glass are joined by creating an outer layer and forming a hollow at the end. After that piece has been blown another piece is of molten glass is blown inside of it and then the whole piece is reheated so that the two layers fuse together. These different techniques can be used to make beautiful glass pieces.

These processes require a good amount of heating and cooling the glass which is why borosilicate glass is usually a better choice for artistic glass work or packaging. This is besides the fact that borosilicate glass is much stronger and more durable and chemically resistant than soda lime glass which is why it is used in beakers and Pyrex storage containers. Unlike soda lime glass which is commonly thought to have been found by accident, Borosilicate glass was engineered to be stronger, to expand and contract less, and to be more resistant to chemicals. Soda lime glass still makes up 90% of the commercial glass market for soda bottles, windows, and dinner drinking glasses but Borosilicate glass can do these things and do it better and with more style.

The only problem with borosilicate glass is that it is more expensive than soda lime glass and it cannot be tempered as soda lime glass can. There is still a win in that it is more chemically resistant and can be vacuum sealed while soda lime cannot. This would allow for products to last longer on the shelf and it can be colored to be UV resistant just like soda lime glass. It is also stronger than soda lime, so it would not require as much material to make a decent bottle. Overall borosilicate colored glass is a fun choice as a packaging material and is severely underused. It has the potential to be much prettier than any soda lime glass with more options in glass work and it is also more resistant to just about everything.

References

https://www.lehigh.edu/imi/teched/GlassProcess/Lectures/Lecture04_Shelby_ColoredGlass.pdf

https://packagingoptionsdirect.com/battle-of-the-glass-bottles-clear-or-colored

https://sha.org/bottle/colors.htm

https://www.britannica.com/technology/soda-lime-glass

https://glassalchemy.com/blogs/the-formula/the-glass-alchemy-numbering-system

https://arthearty.com/glass-coloring-techniques