The evolution of distribution has moved towards a more unitized way of transporting goods from one place to another. The reason being is because businesses are having to distribute large amounts of goods faster than ever in the 20th century. This is when the ‘pallet’ became one of the main ways to transport a unitized load. Pallets provide a way for product to be packaged tightly and to not be loose as well as be protected during shipment. According to Packaging Revolution, a pallet is defined as, “(…) a flat structure used as a base for the unitization of goods in the supply chain” and goes on to explain, “Pallets are used to stack, store, protect, and transport materials in the course of being handled by materials handling equipment such as forklifts, pallet jacks or conveyors, being stored in racking or bulk storage or being positioned in transport vehicles” (www.packagingrevolution.net). Packaging Revolution mentions how pallets get stacked which is another reason why they’re ideal. Stacking pallets is a good method due to saving space and allows shippers to easily keep up with the product. The pallets that are being stacked must have a way to be handled which is where the forklift comes into play. A forklift can pick up heavy pallets and maneuver them through a terminal. Pallets must have an opening to be lifted by a forklift which is why the type of pallet is important. Although there are many different varieties of pallets, most of them have the same qualities. This magazine article will discuss a typical wooden pallet. Their qualities include: top deckboards, stringers, skids or blocks, and bottom deckboards.

When choosing qualities to have on your product’s pallet, you must be familiar with each style. Here is a picture depicting the three main styles of wooden pallets:

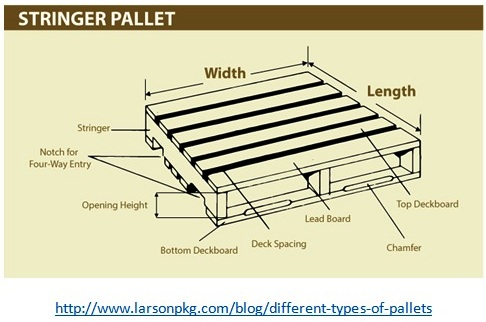

The “stringer style” pallet is one of the most common styles. It has top deckboards to support the load with long pieces of wood perpendicular to them called ‘stringers’ or ‘runners’. Bottom deckboards are then placed under the stringers going in the same direction as the top deckboards. Adapt A Lift Group explains the stringer style pallet when they state, “The stringer design utilizes runners – wood components that run the full length of the pallet... The top deck is fastened to the top edge of the stingers” (www.aalhysterforklifts.com.au). On a four-way entry pallet, there are notches on the exterior layers of the stringers to allow a forklift or pallet jack to enter and pick up the pallet on the length side. Then there is an entry way created by the stringer design on the width side.

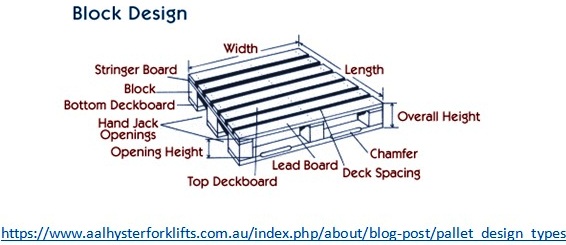

A “block style” pallet essentially has the same objective as the stringer style. The difference is instead of stringers supporting the top deckboards, there are eight cylindrical posts supporting them and the bottom deckboards. There are three cylindrical posts on both length exteriors and two in the center of the load. This style of pallet would be considered a four-way entry.

A “skid style” pallet has absolutely no bottom deckboards. There are only top deckboards supported by two stingers or in this case “skids” on the exterior length sides. This would be considered a two-way entry pallet since it can only be lifted on the two width sides.These three styles are the most popular ways to make a wooden pallet but since there is no set standard way, there are other styles made depending on the manufacturer’s needs and wants which also applies to size/measurement of them.

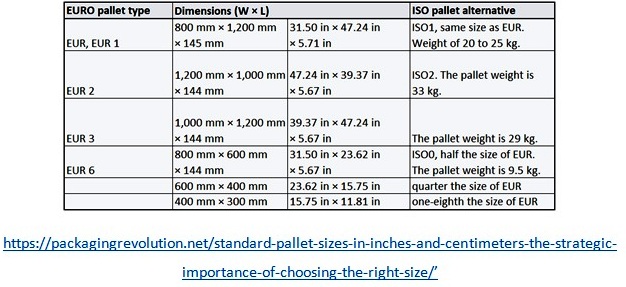

Pallet dimensions are important because during freight transportation, it is easier to have them as a uniform size rather than all different shapes and sizes. It is also important to have set pallet dimensions when delivering to the same company such as, Costco, because they put their product directly on the floor in pallets for customers to buy. Freight Quote explains pallet dimensions when they say, “The Grocery Manufacturers Association (GMA) influences the consumer-packaged goods industry around the globe...They suggest standard pallet dimensions to be 48”x40”...Pallets of that size are commonly referred to as GMA pallets” (www.freightquote.com). GMA takes over most of the distribution market and has more than 30% of their pallets produced in the United States. More common pallet sizes in the U.S. are 42”x42” and 48”x48”. Pallet sizes in other countries change based on their certain needs and uses of the metric system. The different European pallet dimensions are shown below:

Considering that GMA is one of the largest ways to distribute pallets, there are significant factors regarding the sanitation process since they are dealing directly with food. Wood is a porous material which allows bacteria to easily grow and develop mold. Therefore, wood pallets must be sanitized a certain way in order to keep the bacteria from growing. Authors, Gunilla Beyer and Brina GudbjÖrnsdottir, in Wood in the Food Industry, explain the different sanitization processes wood can go through when they say, “The pallets can be pasteurized by using: heat treatment by adding an additional drying cycle in a kiln; high temperature treatment; microwave technology, which seems to be one very promising method” (Beyer & GudbjÖrnsdottir 5). They mention ‘kiln’ which is defined as a furnace or oven for burning, baking, or drying, especially one for calcining lime or firing pottery. They also go on to add that microwave technology is used in the egg industry. Even after having all these sanitization processes, wood pallets can still have potential for bacterial growth. Therefore, it is suggested to have the food in secondary packaging on the pallet such as a box to not be in contact directly with the pallet.

Wooden pallets provide a way for products to be shipped in bulk by being a rigid and flat structure that can be easily lifted and stacked using a forklift or pallet jack. Stringer pallets, block pallets, and skid pallets are some of the most common styles of the wooden pallet. The Grocery Manufacturer’s Association dominates the freight transportation market in the U.S. and in turn has created their own standard size to be 48”x40” to be placed inside stores. Because of how porous wood is, pallets must be sanitized through a special process.

References

Beyer, Gunilla, and Brina GudbjÖrnsdottir. “Wood in the Food Industry.” Www.medinetara.it, www.medinetara.lt/files/media_images/Report-8_kEiaY.pdf.

“Logistics & Materials Handling Blog.” Adaptalift Hyster Forklift Rentals and Sales, www.aalhysterforklifts.com.au/index.php/about/blog-post/pallet_design_types.

“Standard Pallet Sizes.” Freightquote, www.freightquote.com/how-to-ship-freight/standard-pallet-sizes.

“What Is a Pallet?” Packaging Revolution, packagingrevolution.net/pallets-introduction-to-pallet-usage/.