As the packaging industry continues to adapt to meet societal, cultural, and environmental changes, there is a major focus on the convenience of shipping perishable goods from businesses to consumers all over the world. A perishable shipment requires the use of an insulated material in conjunction with a coolant to help prevent spoilage of the product contained within. Products such as food, medical devices, pharmaceuticals, diagnostics, and other temperature-sensitive goods rely on these containers and coolants to prevent spoilage during a varying temperature and humidity transit. Containers used can vary from manufactured foam products to natural, fiber-based applications while coolants used can vary from soluble solutions that adapt to gases compressed to a solid or a liquid.

Foams

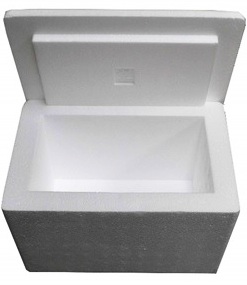

Expanded Polystyrene, otherwise known as EPS, is the most common container used in perishable shipments. Expanded Polystyrene is a lightweight, rigid, closed cell insulation that is available in several compressive strengths to withstand load and back-fill forces. This closed-cell structure provides minimal water absorption and low vapor permanence (3). Polystyrene has a long shelf life, making it convenient and cost-effective for businesses. It doesn't grow mold or bacteria, so it stays sanitary in storage, and helps keep food safe. The downside to EPS chemical stability is, once in the environment, it can remain for generations (18). While EPS is considered green because it does not contain any CFC’s or HCFC’s, it does not biodegrade in nature and can last for up to a million years depending on the conditions (18).

Either as six panels or two-piece coolers, EPS foam has remained the traditional packaging product for insulated shipments (Kodiak). EPS comes in a variety of thicknesses, but the most common sizes used are 1” planks and 1.5” thick coolers. Densities vary as well ranging from 0.75lbs to 3lb per cubic foot (3). At 1.0pcf, EPS provides a typical R-value between 3.85 and 4.17 per inch (4).

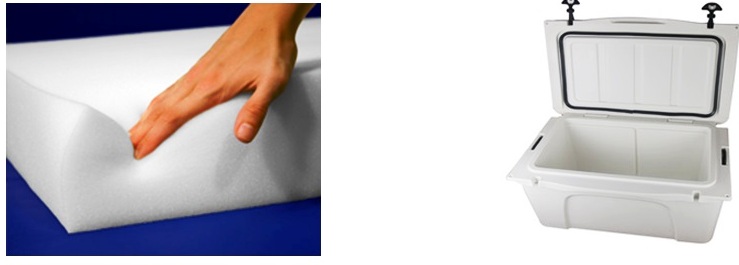

Polyurethane foam, otherwise known as PU, is used for either in a rigid or a flexible state. Polyurethanes are formed by reacting a polyol with a diisocyanate or a polymeric isocyanate in the presence of suitable catalysts and additives. Because a variety of diisocyanates and a wide range of polyols can be used to produce polyurethane, a broad spectrum of materials can be produced to meet the needs of specific applications (5). Rigid PU planks are lightweight, closed cell foam applications found in both packaging and residential insulation. The most common size of rigid PU plank is 1” thick. Densities can vary between 1.8lbs to 6lbs per cubic foot (6). Flexible polyurethane can be found in plank form or spray foam application. These applications are lightweight, open-cell structures that offer better cushioning and support properties than the rigid, closed-cell applications. As a spray foam, molds can be created to act as insulated shipping containers similar to the construction of an EPS cooler. Many companies use this expanding foam within their roto-molded coolers. Flexible foam densities range from 3lb to 50lbs per cubic foot (6). Other flexible applications can be found in a large amount of consumer commodities outside of packaging protection and insulation as well. Polyurethane has one of the highest insulating R-values of all commercially available products today with typical R-values in the range of 5.5 to 8.0 per inch (5).

Recycled Polyester, or recycled polyethylene terephthalate, is a lightweight and recyclable plastic used to make thermal liners for perishable shipments. These liners consist of recycled plastic bottles that were melted down and spun into fibers to create the open cell insulation. Thicknesses vary between 0.375” to 3.0” thick with the most common size being 1.5” for the 2-part liners used with corrugated boxes (7). Since the liners are made up of Type 1 plastic, they can be recycled again and again for future usage. Insulation R-values can vary between 0.5 to 4.2 per inch.

Natural Fibers or Minerals

Rockwool, or mineral wool, is an insulation used in packaging and in homes to replace fiberglass. It is composed of strands of rock and constructed into a thick dense mat (16). This makes Rockwool a natural and sustainable material that is able to trap air and slow the transfer of heat (16). It is also water repellant which makes it great in shipping perishables. Only a few companies are manufacturing it for use in packaging. Thicknesses vary but the common thickness in packaging is 1.5 inches. R-values are 3.0-3.3 per inch.

Flocked Cotton and Flocked Denim are a post-consumer recycled insulation used more frequently in the food industry and home meal kits. Both cotton and denim materials are recycled to form an insulation liner with either a paper or a poly substrate, depending on the application. Both products are recyclable and offer efficient cushioning for food products. Densities and thicknesses vary based on applications with 1” thick being the most common. R-values are similar to fiberglass insulation (17).

Paper based materials are used for normal shipping methods, but can also be used for perishable shipments as well. Products such as corrugated board, Hexacomb, Jute, and padded paper applications can offer small thermal properties as a foam replacement. Most paper based products are cost effective, versatile, and lightweight solutions to fit a customer’s needs (1). Thicknesses vary based on type of insulation being used. While the R-values for paper based products are less than standard foam applications, these products can be used in short time frames for shipping.

Starch Plank, otherwise known as green foam, is a naturally, environmentally friendly packaging material that was created to perform similar to petroleum based foam products while being eco-conscious and biodegradable (2). One con associated with starch is moisture can degrade the product immediately; however, new moisture barrier films are being introduced to help combat this and maintain its biodegradability. Thicknesses can vary between applications with a common thickness being 2 inches. R-values are not published, but temperature testing shown have provided similar results to EPS foam.

Advanced Engineered Solutions

Vacuum Insulation Panels (VIPs) are ultra-thin, high-performing insulants that can be up to 20 times more effective than traditional insulation products. VIPs consist of a rigid, highly-porous core material encased in a thin, gas-tight outer envelope, which is evacuated and sealed to prevent outside gases from entering the panel. The combination of porous material and the vacuum results in an extremely high thermal resistance, which allows for thinner insulation in applications where space is at a premium (8). Current VIPs consist of a silica core and glass fibers. Thickness of the panels are kept thin usually between 0.25 – 1.5” (8). R -values are much higher than standard materials in the range of 30-60 per inch.

Aerogels are advanced, super lightweight, and highly porous solid materials having a large surface area that are prepared by replacing the liquid from a gel with air, which preserves the gel’s three-dimensional structure (9). Thicknesses differ depending on the application, but can be very thin. R-value for aerogels depends on the amount of air removed from the gel material, but can be as high as R-50 per inch (10). This technology is constantly growing and changing as manufacturers are looking at different materials to use depending on industry needs.

Coolants

Refrigerant Packs, sometimes referred to simply as gel packs or cold packs, are coolants used in shipping perishables to maintain the products at a frozen, semi-frozen, or refrigerated state during shipping. These packs can be constructed of gel or foam using various polymers and open cell foams, respectively. These are widely used in the food and medical industry and are the most common coolant used in shipping. Thicknesses can vary with the average size being 1” thick (14). Phase changes can take place between -23 degrees Celsius to 0 degrees Celsius.

Dry ice, carbon dioxide in its solid form, is a dense, snow like substance used as a refrigerant, especially during shipping of perishable products such as meats or ice cream (15). Its temperature is at −78.5 °C (−109.3 °F). Dry ice can be purchased in small pellet forms for easy placement around products or in brick form with increments starting at 5lbs up to 45lbs. This coolant is primarily used to keep items frozen for an extended period.

Liquid nitrogen is the liquefied form of the element nitrogen that is commercially produced by fractional distillation of liquid air. Nitrogen is nontoxic, odorless, and colorless. It is relatively inert. It is not flammable (12). At normal pressure, the liquid boils at -196 °C or -321 °F. Because of its extreme temperatures, this coolant is used for cryogenic preservation of specific biologics and food. In order to transport this coolant safely, a liquid nitrogen Dewar with an outer plastic shell is used.

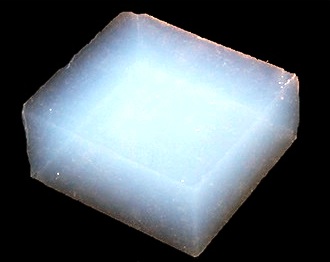

Phase Change Material (PCM) provides advanced thermal protection when shipping temperature-sensitive products. When PCMs melt and freeze, or change phases of matter between solid and liquid, they maintain a constant temperature equal to their melting/freezing point. They are specially formulated to change phases at specific temperatures to match the payload requirements (11). Most phase change materials are used at 0.75-1.0 inch thickness. Different materials can be used to protect products between -20 °C to as high as 27 °C (11).

References

https://www.temperpack.com/perishables/

https://www.greencellfoam.com/hello-coolers

https://insulationcorp.com/eps/

http://www.insultech-eps.com/insulation.html

https://polyurethane.americanchemistry.com/

https://www.generalplastics.com/why-polyurethane

http://cmsgreen.com/packaging

https://vipa-international.org/vacuum-insulation-panels

https://blogs.helsinki.fi/aerowood-project/files/2015/09/Pack-Age-course-story-for-AEROWOOD-project.pdf

https://packagingrevolution.net/american-aerogel-reduces-costs-waste-with-new-reusable-containers-for-cold-chain-shipping/

https://www.cryopak.com/packaging-and-refrigerants/phase-change-materials/what-is-phase-change/

https://www.thoughtco.com/liquid-nitrogen-facts-608504

https://ipcpack.com/

https://therapak.com/catalog/gel-refrigerant-packs/

https://www.britannica.com/technology/dry-ice

https://www.hometips.com/buying-guides/rock-wool-insulation-use.html

http://www.naturalbluethermal.com/

https://sciencing.com/long-styrofoam-break-down-5407877.html