Regardless of any individual's experience with packaging, nearly everybody knows what a pallet is. Pallets are often wooden platforms with holes in the sides of the pallet’s planks that are used for transporting large amounts of material.

However, pallets have been shown to lose strength due to the wood absorbing water from the humidity of the air mixed with stress from top load weight. Over time, this causes wooden pallets to be less and less reliable.

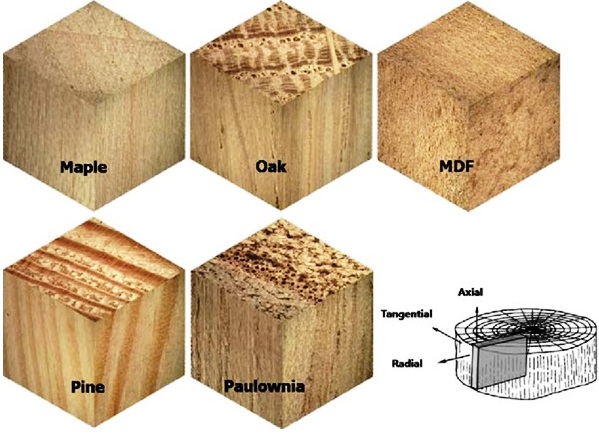

Wooden Pallets are made mainly from three different types of wood. High Density Hardwood is made of materials like Birch, Cherry, Oak, Maple, Ash, Beech, Yellow Birch, Elm, and Red Maple. Low density Hardwood consists of woods like: Walnut, Poplar, Willow, Linden, and Aspen. Softwood on the other hand consists of materials like Cedar, Cypress, Spruce, Pine and Hemlock.

While wooden pallets are very economical and easy to produce, plastic alternatives have been manufactured to last longer and be a stronger alternative. The main advantage of a plastic pallet is the fact that plastic is water repellant. There are many different types of hybrid and fully plastic alternatives that have been created to last longer and to also be manufactured in a biodegradable method.

Molded wooden pallets are wooden pallets of compressed wood. The wood in this kind of pallet is strengthened through high heat and pressure, which produces a more structurally rigid wooden pallet that will last longer.

Taking the whole environmentally friendly perspective, corrugated pallets are built out of regular corrugate consisting of paper and glue. When stacked up properly, this corrugated pallet can hold the structure needed to withstand the pressures that are applied to it. While it is extremely environmentally friendly, it will face the same problem with absorbing water due to the nature of paper.

Engineered plywood consists of plywood with a coating of polyurea over the top. In doing this, the coat strengthens the wood for everyday use.

The use of a hybrid between both corrugated and regular wooden pallets allows the regular wooden pallet to be strengthened by an additional cardboard lining. This gives the pallet a buffer if knocked into other objects while being on a forklift or moved.

All in all, there are many different alternatives to that of a conventional pallet. While the design itself is very economic and relatively reliable, the more recent solutions can provide a more improved green footprint as well as better reliability. While plastics have normally been very durable and easy to produce, it can be hard to find one that would maintain its environmental friendliness. In mixing different materials and creating new age designs, there are many new designs that can replace conventional pallets while also offering more environmentally friendly materials as well as better durability.

References

https://medium.com/@greenstaskes/what-type-of-wood-is-used-for-making-pallets-beb4aadfe02

https://www.mmh.com/article/seven_alternative_pallets_for_greener_operations

https://associated-pallets.co.uk/blog/dangers-high-moisture-levels-wooden-pallets/