Lighting (i.e., light bulbs) is very important today. The majority of consumers look to purchase quality lighting for various reasons. Some of these reasons consist of increased energy efficiency, lower electric bills, and longer bulb life. The five types of common light bulbs are incandescent, fluorescent, compact fluorescent lamps (CFL), halogen lamps, and light-emitting-diode (LED). Consumers can purchase light bulbs in many locations such as Dollar Stores, Wal-Mart, Target, Best Buy, and at local Walgreens. As a result, light bulbs are very essential to many households as well as businesses and companies. Light bulbs have to be packaged properly to safely make it from the distributor to the retailer and into the hands of the consumers. Packaging for light bulbs must also clearly display the product that is within the box. This article will take a deep dive into the primary types of packaging for light bulbs as this is very important in regards to the proper handling of light bulbs due to their fragility.

Primary Packaging of Light Bulbs

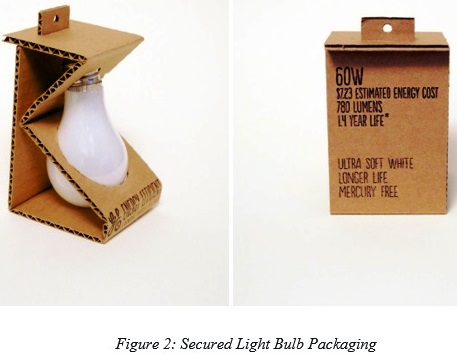

The primary packaging for light bulbs is the box we typically see on the shelf of a retail store. This box serves multiple purposes such as protecting the light bulb from damage while being shipped from the manufacturer. Bulb packaging is not only used to protect the bulbs, but also to provide information about the product such as watts, lumens, lifespan in hours, and energy/efficiency class.

The use of damage-resistant packaging lowers the likelihood of damages to bulbs, which allows suppliers to fill as many orders as possible. Light bulbs can also lose their functionality while on the shelf or during transit, therefore, bulb manufacturers have a responsibility to supply bulb packaging that is sturdy and damage-resistant. The quality of this product packaging is one of the most important tasks for a manufacturer.

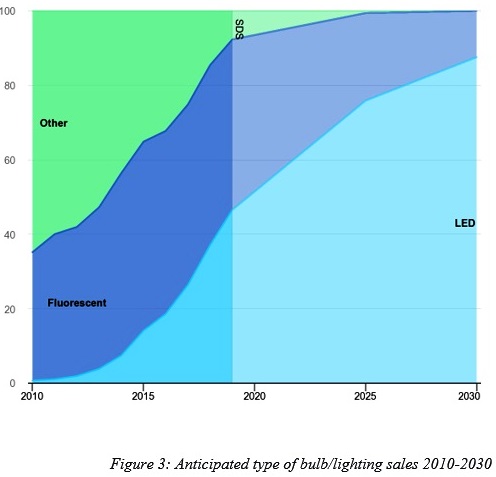

The growth of the global light bulb packaging market is associated with the installation capacity around the globe relating to lighting requirements. These installed light bulbs eventually have to be changed after the duration of their lifespan, which is driving demand for light bulb packaging globally. While incandescent bulbs are witnessing a strong decline in acceptance, CFL (compact fluorescent lights) and LED (light-emitting-diodes) light bulbs hold major parts when it comes to the global bulb packaging market.

Lamp Labeling and Lamp Packaging

Lamp labeling has to include five things. The first thing it must include is Energy Star Partner, lamp manufacturer, or brand name. The second thing it must include is the lamp model or retail SKU number consistent with the model number or identifying information on the Energy Star listing for certified models. It must also include lamp nominal correlated color temperature including “Kelvin” or “K. The fourth thing it must include is the Rated wattage in watts * lamps not covered by FTC requirements.* The final set of information the label must include is for lamps not covered by FTC requirements, lamp rated lumen output in lumens, or lamp nominal beam angle in degrees for applicable products (i.e. MRX, MX). 2

Lamp packaging combined with marketing is essential for companies when it comes to selling their respective light bulbs. “Rapid growth of urbanization and soaring population, particularly across APEJ countries, are factors estimated to propel demand for lighting products, thereby fostering growth of the global bulb packaging market. Demand for LED bulbs is witnessing a rise owing to its performance with high efficiency. LED bulbs will account for half of the global demand for light bulbs during the forecast period. This will further drive growth of the market. Shifting consumer preferences towards e-retail has transformed packaging to become more prominent than before. E-retail is estimated to register an impressive growth in the near future, affecting the market for light bulb packaging. This is further expected to drive demand for light bulbs, and thereby its packaging globally.” 1

“Requirement for protection of light bulbs against physical damages at the time of transit have paved opportunities for innovation in light bulb packaging. Plastic is a preferred material for light bulb packaging, owing to its high insulation properties. However stringent rules imposed by regulatory authorities on the utilization of plastic is likely to inhibit the growth of the market. Increasing usage of eco-friendly materials for the production of folding cartons and paperboard offers more opportunities for the growth of the global bulb packaging market. Moreover, sustainable and reusable packaging techniques are likely to further influence growth of the market during the forecast period.” 1

Light Bulb Testing

Light Bulb packaging is always important due to its fragility, but testing is something that is arguably more important prior to the shipping/transport of this product. “A pre-shipment lighting inspection with rigorous on-site lighting testing can help you avoid safety issues, as well as functional and performance issues with the products. Lighting testing can also help you ensure compliance with LED lighting safety standards and international regulations.” There are about 11 tests that should be considered when testing particularly LED bulbs since they are on a popular to consumers. These 11 tests consist of the following: Rub test on lighting rating label, fatigue test, assembly check, torque tests for lighting components, HI-POT test, function test for lighting, endurance testing, internal check against a component data form, item drop test, lighting source/integrating sphere test, and Electromagnetic Compatibility (EMC) Test.

LED lighting importers typically market lights as meeting certain brightness, colour, or efficiency standards. An integrating sphere test can measure the lighting source using common metrics, which help confirm the production units meet these standards. This test requires an integrating sphere system with a spectroradiometer for spectral mismatch corrections and computing software. Most lighting manufacturers should have both the equipment and related software available on-site already, as they are essential for LED lighting manufacturing. The inspector places the LED light inside the integrating sphere and then observes the results via the computer software. The recommended sample size for this test is at least three units.3

Conclusion

The need for proper light bulb packaging is essential for both the manufacturers and consumers. The manufacturer has the responsibility to make sure the consumer has a safe and durable product at the end of the day. There are many options out there when it comes to light bulbs whether you want CFL, LEDs, or dimmable lighting which is similar to going to a grocery store and looking at the nutritional facts on the back of the box. Similarly, the overall packaging and facts about the light bulbs allow the consumers to choose what is best for them.

References

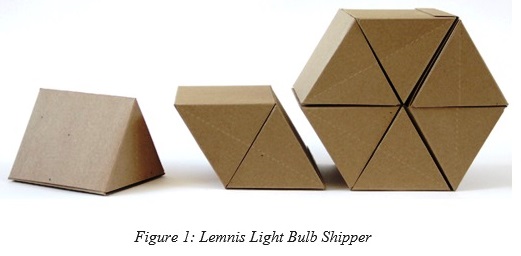

Figure 1 https://www.zdnet.com/article/packaged-goods-three-innovations-in-shipping/

Figure 2 https://www.packagingoftheworld.com/2013/04/environmentally-friendly-light-bulb.html

Figure 3 https://www.iea.org/data-and-statistics/charts/lighting-sales-by-type-in-the-sustainable- development-scenario-2010-2030

1. https://www.transparencymarketresearch.com/bulb-packaging-market.html

2. https://www.energystar.gov/sites/default/files/ENERGY%20STAR%20Lamps%20V2.1%20Final%20Specification.pdf

3. https://www.intouch-quality.com/blog/lighting-testing-11-on-site-tests-for-led-lighting-inspection