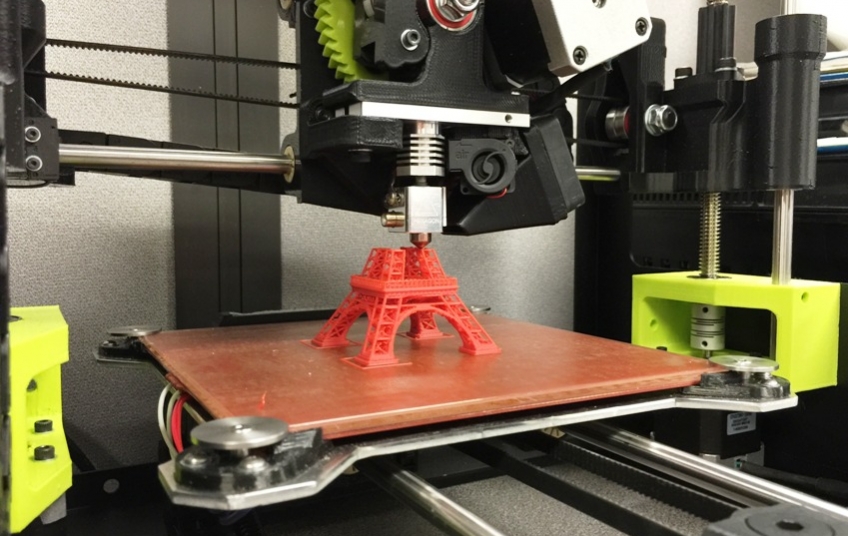

Three-dimensional printing can accelerate early-stage product development through rapid prototyping. It encompasses a wide range of manufacturing technologies. Each of these different manufacturing tech industries make objects in layers that are usually about 0.1mm thin. The methods used vary significantly, but all start with a computer aided design (CAD) model or a digital scan. This is then processed by a “slicing software” that divides the object into thin cross sections that are printed out one on top of the other.

3D printing helps companies design molds so that the prototypes can be manufactured quickly and economically. With this in mind, we see that 3D printing can rapidly expedite the time and cost it takes to bring a product to the market. The single parts or a limited number of parts that is fabricated is cheaper than using standard plastic processing techniques like injection molding, thermoforming and blow molding.

With 3D printing, one can go from a CAD blueprint to a complete part in a matter of days or hours. This will impact packaging machinery manufacturers. Some ways that it will do this is by being able to print robotic arms used in production. The benefits are that it will be lighter and more powerful with the right choice of material and printing method. Companies will make spare parts for machinery by making them on spot instead of being supplied from all around the globe.

Who Could Benefit?

While personalized 3D printed packaging could benefit many sectors, it could be a particularly helpful tool for food and drink brands. Personalization can be especially attractive for gift packaging when consumers want something special such as a special occasion or holiday. Sustainability can benefit from this. Not only is 3D-printed packaging increasingly made of environmentally friendly bioplastics but once discarded, the plastic waste can be easily cleaned and recycled into new printable plastic. The process itself hardly produces any waste as there is never excess material that requires cutting.

In the future it could be possible to print packaging based on how much a costumer is buying. This will help reduce waste and the volume of packaging that goes into the bin. It allows engineers, designers, managers, and operators to check designs for usability, appearance, fit and function prior to committing to traditional processes. Providing efficiency, accuracy and trust in design.

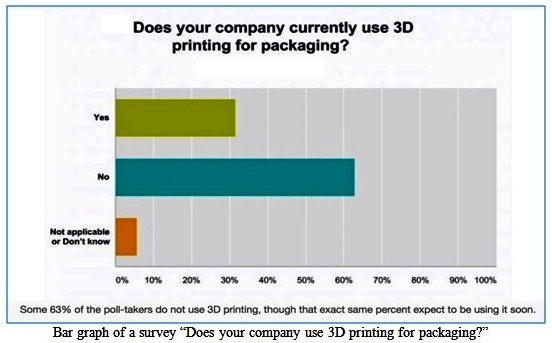

Having a 3D printer make a rapid prototype will help to see an accurate representation of the packaging before it is in high volume production. Saving in labor and production costs. In the graph above we see that most companies using 3D printing use it for prototype containers. It is more valuable if an item is in someone's hands rather than just a picture. It provides fast, accurate prototypes that is good for feedback when it comes to developing new packaging or modifying the current packaging. It also offers rapid prototypes without tooling costs. Below is a bar graph from a survey done which asks if their companies use 3D printing for packaging. It was found that over one-third of respondents were already using 3D printing for product packaging and the others plan to do so in the near future.

What are some challenges that may occur?

There are challenges that occur when using utilizing 3D printing. One of them deals with cost, personalizing packaging is more expensive than of standard packaging. Costumers will have to pay more for those personalized items. Another challenge is that the companies are required to include certain details, such as images and legal information. In this case the consumers would not be allowed to be in full control of the design for the package. A way to go about this is to provide the customer with a choice of templates with an option of details that could be personalized before being printed. Having a standardized packaging would be less complicated, by only personalizing an outer sleeve or other form of gift wrap. The amount of consumers that are interested in this new idea is increasing meaning the challenges that will be faced with 3D printing is worth it. It will certainly be very interesting to see how creative companies will makes use of this technology.

References

https://www.prescouter.com/2017/02/3d-printing-disrupting-packaging/

https://www.explainingthefuture.com/3dprinting.html

https://www.packagingdigest.com/digital-printing/3d-printing-4-packaging-poll-shows-mixed-results

https://www.packagingdigest.com/digital-printing/3d-printing-expert-shares-packaging-insights

https://www.packagingdigest.com/digital-printing/3d-printings-future-in-packaging-is-promising1507