As technology advances, the cost of standardized packaging machinery increases while price for production of packaging containers decreases. The demand for medical materials, food, and e-commerce has made the substantial economic contributions in the field of global packaging over the past decade. The United States and Japan account for raking in the most money and contributing over 59% of the national markets for packaging production. Together they acquire over $400 billion in profits. Although packaging is a market that is consistently growing, there is always room for expansion. The growing supply chain is always looking for innovative ideas for product management to increase production but minimize cost.

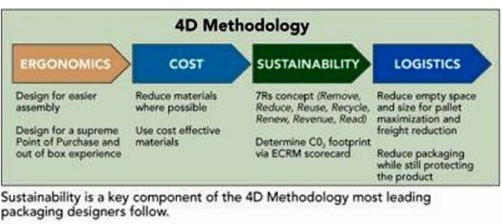

There are five packaging techniques that are commonly used as basic materials for storage which include crates/pallets, shrink wrap, vacuum packaging, shock mount packaging, and preservation packaging. The corrugated cardboard boxed is a standard material for shipping, but isn’t a compatible commodity for all shipped goods. Food and medical supplies require special handling care and thermal protocols. During the economic recession in 2008, recycling became an even more relevant, widespread monetary inclination. For the past decade, markets have assessed the cost of production for packaging and wastage of materials, and how they both affect the environment. To reduce both factors of materials synonymously, manufacturers developed a methodology to analyze the market and produce ecofriendly materials that are reusable and resists damage under tremendous amounts of weight and outside factors that may alter the original physical state of packages. Figure 1 exhibits the most common and useful assets for any company distributing products, especially those who specialize in logistics take into consideration when marketing.

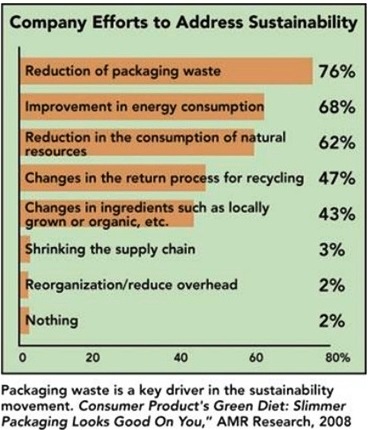

In 2008, $500,000 in packaging materials were saved by the slogan, “reduce, reuse, recycle” that later became a household term. In 2014, IBM revolutionized the packaging industry by creating technology that creates lightweight materials, specifically corrugated boxes, and produced impressive strength ratios. Other major manufacturing companies bought in to the slogan as well which assisted in the drastic decreased the use of raw paper material. They began utilizing eco-friendly facilities and manufacturing plants whom of which claim to conserve energy and strictly use biodegradable materials. Cost factors of manufacturing included the cost of space, operation, and product assignment with inventory of box sixes and custom shipment container accessories. To minimize the cost of shipment, a small range of box sizes are available per analyzation from the manufacturer. Product size is factored in the overall cost in packaging losses. It consists of 10% of the distribution economy. Figure 2 shows a projection of approximate expectations of cost for a profitable logistic company.

In the field of packaging, the old saying “waste not, want not” is a requisite. Scrap rates have increased by 20% since 2012, and market sizes are skyrocketing in all factors of the packaging industry. The intensiveness of capital gain comes from advancements in machinery and improved capex levels for means. Packaging is one of the fastest-growing industries in the world and will continue to grow exponentially and save the planet in synchrony.

References

Wilson, Richard C. “A Packaging Problem.” Management Science, Vol. 12, No. 4, Series B, Managerial (Dec., 1965), pp. B135-B145. INFORMS.

http://www.jstor.org/stable/2627807.

Ray, Arabinda. “The Economics of Packaging.” Economic and Political Weekly. Vol. 3, No. 7 (Feb. 17, 1968), pp. 333+335-336.

Worrell, Ernst and Sluisveld, Mariësse A. E. van. “Material efficiency in Dutch Packaging Policy. Philosophical Transactions: Mathematical, Physical and Engineering Sciences. Vol. 371, No. 1986. Material efficiency: providing material services with less material production (13 March 2013), pp. 1-15.

Figure1: Humphrey, Ryan. “Sustainable Packaging Initiatives Are a Viable Cost-Reduction Solution in a Downward Economy”. Industry Week Publications. Penton. 2017. Print.

Figure 2: Humphrey, Ryan. “Sustainable Packaging Initiatives Are a Viable Cost-Reduction Solution in a Downward Economy”. Industry Week Publications. Penton. 2017. Print.