Introduction

Packing peanuts are ubiquitously used throughout the shipping industry. The peanuts serve two purposes, to fill void space around a packaged item and to increase cushioning to decrease impact force on the item. The most widely used peanut is made from Styrofoam, created in 1965 by Dow Chemical Company, a non-biodegradable material, it is also called by the generic name: expanded polystyrene plastic.1 As humanity’s impact on the Earth is starting to become abundantly clear, with climate change and non-recyclable materials polluting our lands and water, alternative ways must be found for things as simple as Styrofoam packing peanuts.

Waste from Packaging

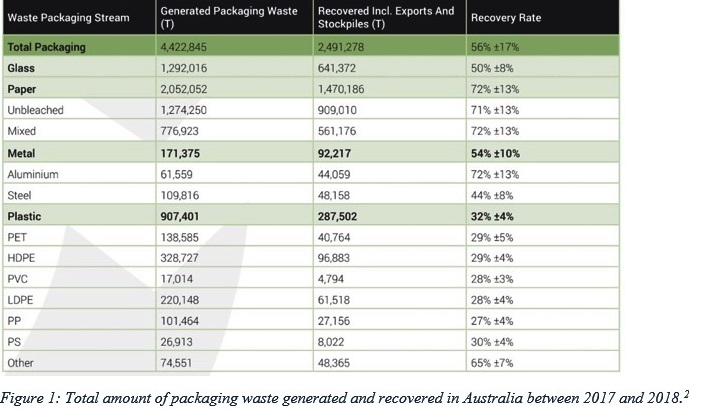

In a study of packaging water conducted between 2017 and 2018, it was found that only 56% of packaging materials are recycled. The results from this study can be seen in Figure 1. The study only covers the waste of Australia, a county of only 25 million people to the US’s 350 million. It shows just how much waste is generated in a developed country from shipping alone. Figure 1 breaks down the generated versus recovered tonnage by material, and then calculates a percent recovered or recycled. The data shows that paper products, including cardboard, have the highest recovery at 72%, and plastics have the lowest recovery at 32%, this figure would include Styrofoam peanuts. The study shows that PS, or polystyrene, makes up for about 0.61% of packaging materials, and 0.98% of materials not recovered. This study uses the weight of items to show usage and recovery, but Styrofoam is designed to have a very low density, especially in comparison to paper and metal. If the study looked at the volume of materials, the metrics may show a very different story. The density of Styrofoam is 0.05 metric ton/m3 and cardboard has a density of 0.689 metric ton/m3. This would drastically change the scale as now it would show just how much space is taken up in landfills and the ocean by Styrofoam packing peanuts.2

The Rush for Green Packaging

As humanity is starting to understand the extent to which they are polluting the world’s oceans and lands, the need for new sustainable material is starting to grow more and more. As shown in the previous section, packaging has created mountains of waste and is one of the best places to start the push for green solutions. Figure 2 shows green materials used for packaging. The first listed is a starch-based biomaterial. The material is based on cornstarch and has numerous uses from packing peanuts to soap bottles. Next is PLA, or polylactic acid. PLA is a biodegradable plastic that can be used for bottles and molded packaging. Corrugated bubble wrap is created using cardboard instead of plastic, like traditional bubble wrap. This makes it completely biodegradable and recyclable. Mushroom-based packaging uses the mycelium of mushrooms and is being used by Ikea as an alternative to Styrofoam. Recycled plastics are a great way to use non-biodegradable materials again. Although they will not be biodegraded, they ensure that the plastics do not go to landfills or, even worse, the ocean. A new trend is organic fabrics, specifically hemp, flax, cotton, and leaves. These materials can be used to replace plastic bags in the shopping industry. Finally, there are refurbished products, which is just another name for recycling materials that otherwise would not be. This would include things like bulk bags, the reuse of Styrofoam, and polystyrene.2

Starch Packing Peanuts

There are many alternatives to Styrofoam peanuts in use today, one of these is made from corn starch. These peanuts are developed with the Earth in mind, as it is compostable and readily decomposes in water. Figure 3 shows the decomposition of this material.

The major advantage of this alternative is that the starch peanuts have almost the same shipping properties as Styrofoam and act as a good substitute. Another major advantage is starch peanuts produce no electrical charge, unlike Styrofoam, and thus can be used in shipping electrostatic-sensitive objects.5 The last major advantage is they are completely edible. This means if they are not disposed of properly and end up in the ecosystem, an animal can ingest the peanuts and it will not harm them. The major drawback of this type of peanut is that it is heavier than Styrofoam. With the added weight of this material, it will increase the overall weight of the package, thus adding an additional cost of shipping, as most shipping providers charge by weight. This will mean a good deal of businesses will choose Styrofoam, as it will decrease their overall shipping costs.5

Crinkle Paper

An up-and-coming replacement is what is known as crinkle paper. This is paper that has been folded multiple times, making it look and act like a spring. This paper acts as a good method of filling void space and provides protection to items as a cushion for impacts. Since this product is made from paper, it is completely biodegradable. Another major advantage of crinkle paper is it can be made from any paper source and does not necessarily need to be bought. A company can purchase a machine that can both shred unwanted documents and be used as a filler for their shipments. In tests conducted by Christian Brothers University, the crinkle paper even performed better than the packing peanuts as a cushioning material.4 Crinkle paper has been making large strides in the small business community, especially in crafting.

Bamboo & Paper Cardboard

Cardboard is starting to take the place of plastic in form-fitting packaging. New advances have allowed bamboo to take the place of plastic in a lot of shipping products. Bamboo is rapidly available for use all around the world. It is one of the fastest-growing plants, which means it can keep up with the ever-increasing demand of today’s economy. It is also extremely cost-effective for major manufacturers. The added benefit of bamboo is that it is completely recyclable and biodegradable, making it completely green. With today’s technology recycled cardboard, whether it be bamboo, paper, or both, can be ground down into a pulp and injected into molds. These molds allow for the cardboard to be made into any shape imaginable.1

Polylactic Acid (PLA) Plastics

PLA is a rising star in the biodegradable materials field. PLA is a plastic that is made from lactic acid, found readily in the environment. PLA can be extracted from many plants and agricultural waste, including corn, sugarcane, and beets. In 2019, Coca-Cola has started to invest in its PlantBottle brand, which is comprised of 100% plant-based material. PLA can be used in many other fields. It is used widely in 3D printing, making it very malleable for use in packaging. PLA can be customized for each package using a 3D printer, making it perfect for specialty shipping. The biggest drawback of PLA is its low melting temperature, making it infeasible for high-temperature destinations.

Weaknesses of Sustainable Packaging

The biggest weakness of sustainable packing is recycling. The average consumer does not understand how to separate recyclable materials, leading to their contamination. In some recycling centers, when there has been contamination of one or more items, the plant will dispose of an entire batch to a landfill or incinerator. In some cities recycling is not offered as a service alongside trash pickup, meaning citizens of that city must take their recyclables to designated drop-off areas, decreasing the usage of recycling services. Then in several cities, especially rural towns in the US, recycling services are non-existent, and all the waste will be sent to either a landfill or an incinerator. In some cities, especially the larger cities of the US, the recycling plants cannot handle the volume collected, and it either sends the extra to the landfill or ships it off to other recycling centers across the world. All of this means that a completely sustainable packaging system must keep in mind that the materials used may not be recycled and maybe a final-use product. 1

Another drawback of sustainable packaging is hazardous materials. No matter how sustainable a package may be made, it may end up contaminated due to what it is protecting. These materials can be anything from highly hazardous chemical agents to nuclear waste. When the packaging has met the contaminant, it will have to be disposed of and may risk further contamination to the environment. The best method to prevent further contamination is to design the package in such a way as to prevent leakage of any material from inside the package to the outside world.

Conclusion

Over the past three centuries, the world has been polluted by industry, leaving trash and debris all over the land and sea. Humanity needs to take decisive action to curb the use of non-sustainable and non-biodegradable materials. In the past two decades, green packaging solutions have become more commonplace. As sustainable solutions, like the advent of polylactic acid and starch products, start replacing outdated and environmentally harmful materials, like Styrofoam and polyethylene plastics, packaging has been greener than ever, leaving a cleaner and healthier Earth.

References

Fackler, A. Inside the Secret Science of Packing Material https://gizmodo.com/inside-the-secret-science-of-packing-material-5640713.

Fackler, A. Inside the Secret Science of Packing Material https://gizmodo.com/inside-the-secret-science-of-packing-material-5640713.

What Is Green Packaging? https://bulkbagreclamation.com/what-is-green-packaging/.

Malasri, S, et al. Product Protection and Packaging Operations Improvement. International Journal of Advanced Packaging Technology 2019, 7 (1), 307–317.

Pros and Cons of Biodegradable Packing Peanuts. https://www.heritagepaper.net/pros-and-cons-of-biodegradable-packing-peanuts/.